Stainless steel is the “green material” par excellence and is infinitely recyclable. Within the construction sector, its actual recovery rate is close to 100%.

It is environmentally neutral, inert and when in contact with elements such as water it does not leach compounds that might modify their composition. These qualities make it a material which is ideally suited to building and construction applications: roofs, facades, rainwater recovery systems, domestic water pipes and swimming pools as well as bridges and pedestrian bridges.

Stainless steel’s longevity fulfils the requirements of sustainable construction. A suitable choice in terms of grade, surface finish, installation and maintenance guarantees the user unrivalled service life.

Construction components in stainless steel are delivered ready to install on site reducing pollution (noise, dust, etc.). Furthermore, during demolition, these can be salvaged for re-use in recycling, adding value.

Stainless Steel 100% recycled

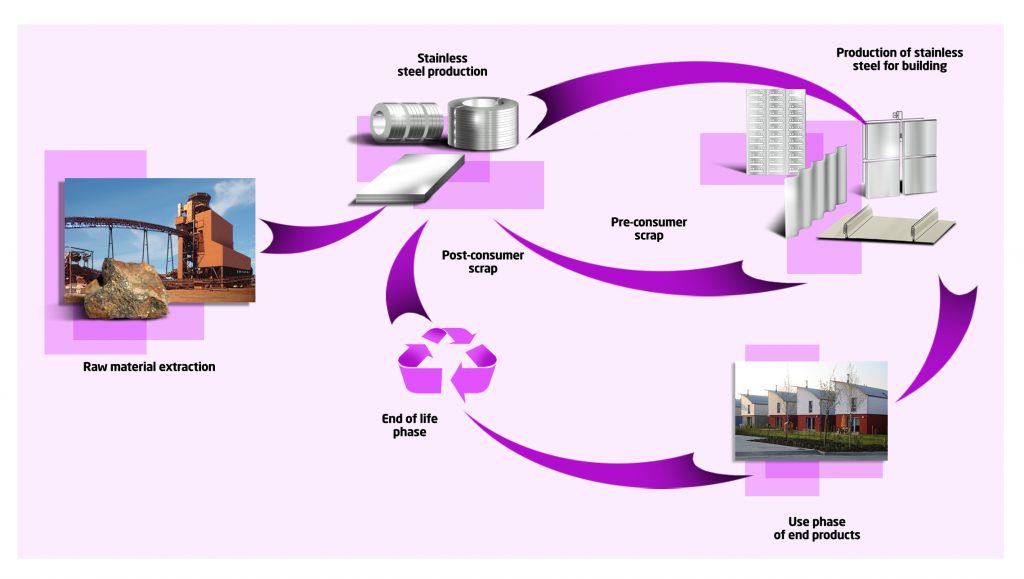

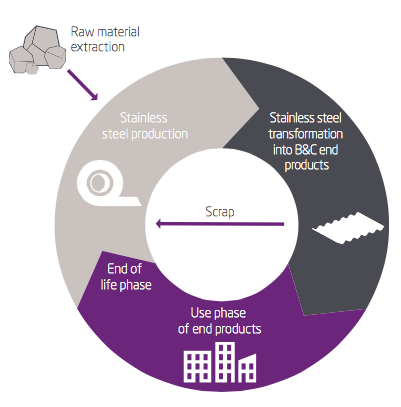

Today, the material flow for stainless products demonstrates that the recycling of pre- and post-consumer stainless steel scrap is already common practice.

In the production of stainless steel, a scrap blend and other raw materials – chromium, molybdenum, nickel and other elements – are melted together in an electric furnace before going into a converter for refining. The molten stainless steel is then cast into slabs or billets, before the production of plate, sheet, coil, wire or other product forms, in preparation for use by industrial manufacturers. These manufacturers produce the stainless steel items we use every day, including cutlery, pots & pans and kitchen sinks, and inumerable architectural, industrial and other components.