UGINOX Patina K44 is naturally resistant to corrosion and suitable for any environment.*

Roofing:

UGINOX Patina K44 will adapt to any location for roofs including coastal / marine areas and installed according to current good practices (e.g. NF DTU 40.44 French Code). When exposed to the atmosphere the Tin coating will develop a natural patina. In roofing applications the change is noticeable after a few weeks and especially following rainfall the process will be substantially complete after a few months.

Vertical cladding:

In vertical cladding or sheltered soffits the surface receives less moisture and the patina will take longer to develop. In such areas, where cleaning operations may also be required we recommend an alternative Aperam facade surface such as UGINOX Top.

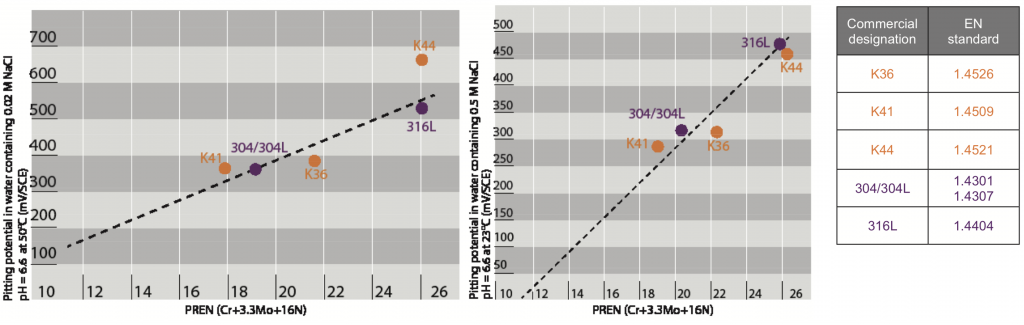

Behaviour to localised corrosion

Along with the tinned coating, the corrosion resistance of the underlying base material is of primary importance.

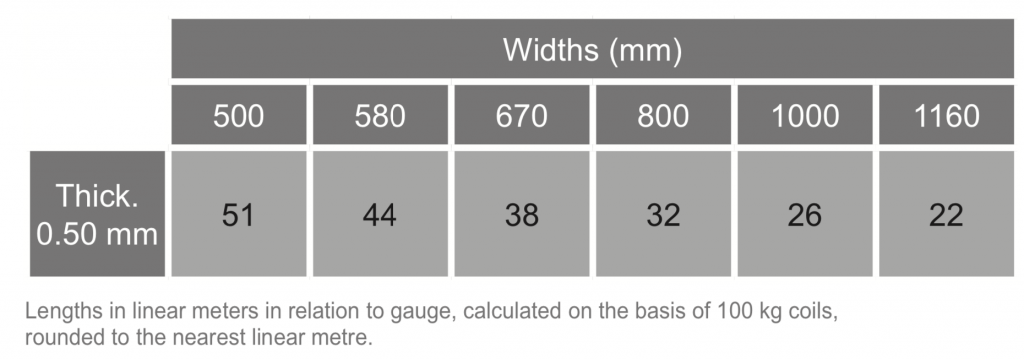

Our dimensional range

- Thickness: 0.5 mm

- Maximum width: 1160 mm

- Available in coil, slit coil and sheet

Recommendations

- Use UGINOX Patina K44 for standing seam, self supporting and cleated seam roofing, as well as for accessories.

- Avoid the use of UGINOX Patina K44 in vertical and sheltered areas.

- Use dedicated tools to avoid any risk of cross contamination.

- Do not work with other metals adjacent to UGINOX Patina K44, which could cause contamination as a result of projections.

- Avoid the use of metallic pads or wire wool including powder based abrasives.

- Before soldering use an orthophosphoric based acid for pickling. Use of chlorine based pickling agents is prohibited. We recommend immediate rinsing with water after soldering.

*While every care has been taken to ensure that the information contained in this article is accurate as possible it should not be used as a guide without further consultation with the manufacturer.